Ultimaker 2+ Product Spotlight

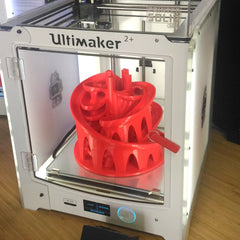

Ultimaker 2+ Product Spotlight

Summary:

- Great printer for testing lots of materials

- Optimized airflow for increased reliability

- Innovative geared feeder for consistent quality

- Easily swappable nozzles

- Our thoughts

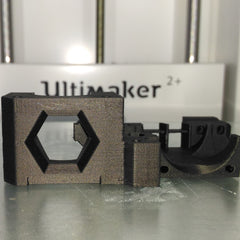

- Our prints

Main specs

| Build Plate | Standard version: 223 x 223 x 205 mm |

| Extended version: 223 x 223 x 305 mm | |

| Build Plate Temperature | 50 to 100 Celsius |

| Nozzle Temperature | 180 to 260 Celsius |

| Layer resolution | 0.25 nozzle: 150 to 60 microns |

| 0.40 nozzle: 200 to 20 microns | |

| 0.60 nozzle: 400 to 20 microns | |

| 0.80 nozzle: 600 to 20 microns |

At Voxel Factory, we offer a free 3-hour training for two people where we pass down all the tips and tricks as well as present you all the main functions of the printer. We also offer a Safety Enclosure for Ultimaker 3D printers (made by Printed Solid) for those who want to print with more complicated materials that require a controlled temperature.

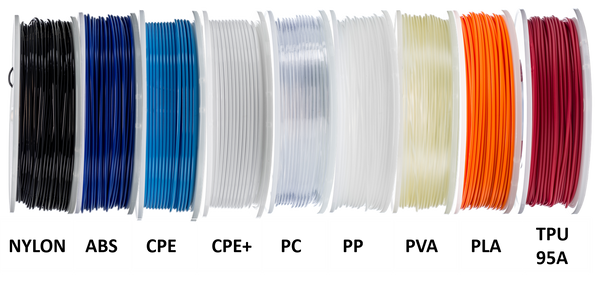

The Ultimaker 2+ is a versatile machine capable of printing with a variety of materials with precision and reliability. It has been tested with multiple filaments, including ABS, PLA, TPU, CPE, CPE+, PC and Nylon. Since the printer is an open filament printer, you can venture outside the usual materials and find the one that suits your needs.

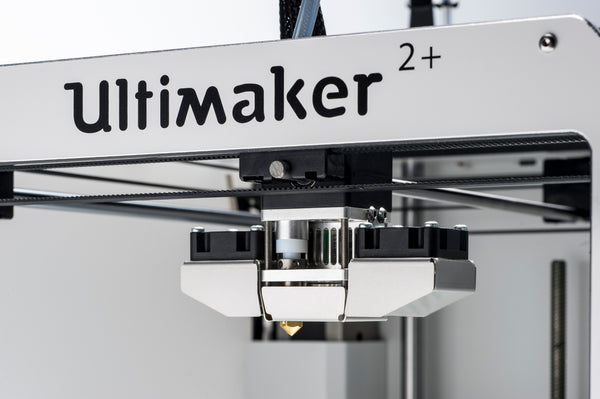

The printer head comes with new fan caps for an optimized airflow that is aimed perfectly below the nozzle to allow needed cooling without affecting the nozzle temperature. The airflow is also calibrated to flow equally from both sides for a smooth finish.

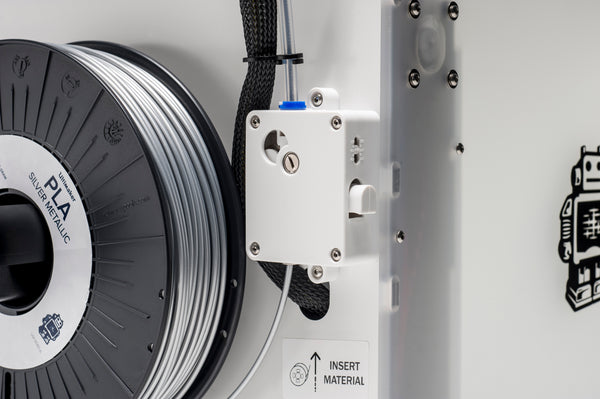

The innovative geared feeder gives you control over the tightness of the gear when its pull the filament into the printer, an important feature to have when experimenting with multiple materials. This comes in handy when you have a project needing some flexible material (TPU).

A whole nozzle kit is included with the printer to give you the chance to start experimenting with different nozzle from the get-go. Important to note that they crafted to be easily swappable without a hassle. Nozzles sizes included are 0.25, 0.4, 0.6 and 0.8 mm. We also carry a 0.5 mm steel nozzle.

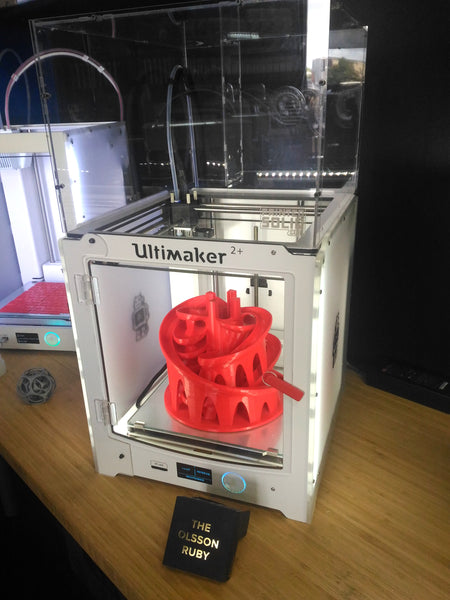

We’ve had quite some time to put the Ultimaker 2+ to the test and explore most of its features. We pimped our machine with an Olsson Ruby to print abrasive materials without worrying about the nozzle. Needless to say, we did some funky stuff and we are pleased with the quality of the prints.

So far, we’ve tested:

PLA from Ultimaker and Materio3D

TPU from Ultimaker (95A), NinjaFLex and SemiFlex

Nylon from Ultimaker and Taulman3D (910, PCTPE, 645)

T-Glase from Taulman3D (a.k.a. PETT)

Carbon Fibre from ColorFabb (XT_CF20)

Here’s a little gallery of what we printed on the Ultimaker 2+

Also, you can play Pong on the printer. Because why not!

- Tags: FDM 3D Printing Ultimaker

- Nathan Orfin