Formlabs Complete SLA Printing Solution

Complete SLA Solution Available at Voxel Factory

With the release of Formlabs Wash & Cure machines and our Partner Support Certification, we can now offer a complete solution package to fulfill SLA 3D printing needs of enterprises, small business and individuals in Canada.

This complete package includes:

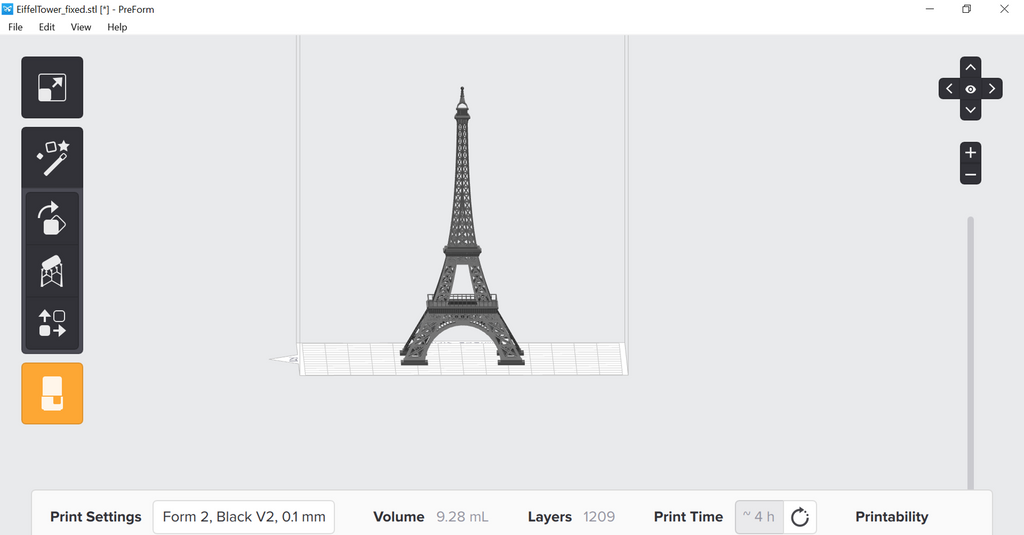

Form 2 SLA 3D Printer + PreForm Software

Benefits

Quality - Unparalleled quality for the price

Stereolithography (SLA) printing works by photopolymerization, or in simple English: a laser that solidifies liquid resin (polymers) by beaming its light in a very precise manner. This process allows a hyper smooth finish. Since the light of the laser is doing most of the work, the printer is not vibrating. Therefore, each print has no visible deformation due to vibrations and it is near impossible to distinguish between layers.

Ease of Use

All you need to do is insert file (.stl, .obj, etc.) in PreForm, click the magic button if you don’t know what to do. You can also play around if the settings if you so desire. Then export (Wifi or USB), insert file in printer, insert resin cartridge, insert resin tank (especially when changing resin), open the air inlet and press print. Final step: Enjoy & wait.

Moreover, the PreForm and Form 2 are constantly being bettered via software and firmware updates. Formlabs have an entire team working full time on innovating the PreForm software.

Reliable/Professional

Formlabs has worked extensively on making sure that their printers are the most reliable on the market. As explained to us by Kevin Gautier when we visited Formlabs HQ in Boston during a Partner Summit, the Form 2 has multiple sensors and mechanisms to give the printer maximum reliability ranging from heat sensors, resin wiping to remove particles from the build plate and lateral movement when changing layers to reduce suction between the print and the resin tank.

All of this (and more) makes the Form 2 an immensely reliable and professional desktop SLA 3D printer for a large variety of uses.

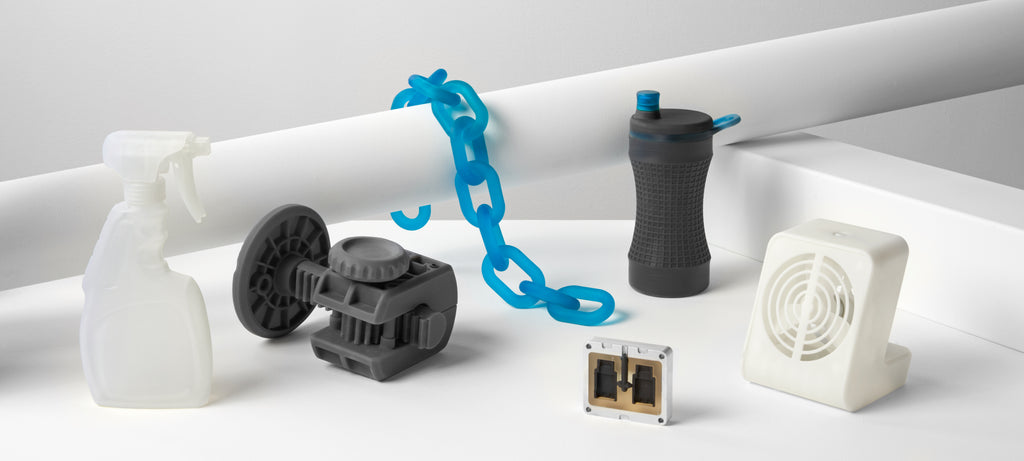

Materials

Large variety of materials are available for multiple use. The printer automatically recognizes the inserted cartridge and refills the resin tank so you don't need to get your hands dirty.

Engineering Series

Every engineering resins attain maximum mechanical and functional proprieties after post-curing.

Tough: Great resin for making robust parts that will receive some stress and strain for short amount of time. Useful for jigs, fixtures and drill guides.

Durable: Very high impact strength, perfect for parts needing low friction and resistance to wearing. Making multiple gears with this resin is a great idea as the material will glide against itself instead of generating friction.

Rigid: Strong, stiff and creep resistant with low elongation due to being reinforced with glass. Thin walls and fan blades are an incredible application of this polymer. Use only with LT resin tank*.

Grey Pro: This versatile material is made for more rigorous and functional applications than the standard resins (not to be confused with Standard Grey). Also has low creep (deformation over time) making the printed parts good for supporting other objects. Use only with LT resin tank*.

Flexible: Ideal for parts that need some flexible movement. Soft to the touch makes the resin a great choice for comfort design part (grips, handles, etc.).

High Temp: You need not be a detective to figure out that this resin is made for parts that need to resist high temperature. Heat Deflection Temperature (HDT) of 289 C, the highest on the 3D printing material market. Also useful for injection moulding (around 100 shots with modification) and thermoforming. Once printed, the internal channels of the part are easier to clean compared to other resins.

*Note: Grey Pro and Rigid need to use Long Term (LT) Resin Tanks, which we also offer. It is required as the polymer used in those two resins are not compatible with the material used to make the standard resin tank.

Standard Use/Prototyping

Grayscale - Black, White, Grey: End result gives a finely detailed print with a smooth surface and matte finish. Can be painted over afterwards. It is not necessary to post-cure, but doing so will make the part stronger, more stable and easier to sand and paint.

Clear: Printed parts are translucent, which makes a cool idea to use LED lights in the final design. Also not necessary to post-cure this resin, but doing so will make the part stronger and more stable.

Color Kit: Make your own color resin with this kit. Comes with a recipe book that contains 16 colors or you create your own with this color picker. Color-Coded Jigs would be a good use for this resin beyond artistic reasons.

Special Uses

Castable: Designed for casting hyper precise parts with smooth finish like rings and other jewelry at a cost-effective price. This material burns out without ash or residue.

Ceramics: This material is not finalized yet, you can inquire more information at https://formlabs.com/materials/ceramics/

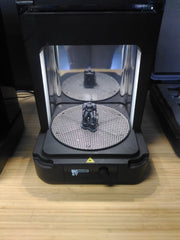

Form Wash - Automated cleaning

After printing with liquid resin, you need to clean up the printed parts from excess liquid. One of the ways to clean the parts is to use the finish kit, it requires to put on gloves and lots of manual work. The other way is to use the Form Wash for easy, automated and reliable cleaning.

How it works:

- Pour 8L of IPA in the Form Wash (Just to avoid confusion, by IPA we mean Isopropyl Alcohol, not India Pale Ale)

- Once the print is finished, you can either put the build plate directly in the Form wash or take the part off the build plate and put the printed part in the washing cage.

- Set the timer and press start.

The Form Wash will then wash the print(s) by moving the alcohol around the pieces and it rinses off the liquid resin from the prints. For optimal results, use fresh IPA.

Post-Wash & IPA

Now, how can we know if the IPA that has been used is still okay to use? Formlabs created a hydrometer to show the percentage (%) of resin in the IPA, which you must first calibrate with a fresh batch of IPA.

Once the washing is finished, the Form wash opens its door and lifts the printed parts out of the IPA which you can take out, let them dry and post-cure them in the Form Cure.

Form Cell Compatibility

The Form Wash is also Form Cell compatible, meaning you can own a medium scale automated SLA 3D printing process that schedules prints and washes with minimum effort and almost no human involvement.

Form Cure – Complete Solution

As mentioned in the materials section, most materials need curing to attain maximal proprieties, especially the engineering materials.

What is the Form Cure and what does it do?

Form Cure is the machine created by Formlabs to complete its 360 solution to SLA 3D printing. As explained to us by the engineers who created both the Wash and Cure, there needs to be both UV lights and heat to cure the parts to max proprieties.

Form Cure is the machine created by Formlabs to complete its 360 solution to SLA 3D printing. As explained to us by the engineers who created both the Wash and Cure, there needs to be both UV lights and heat to cure the parts to max proprieties.

As might be expected, some materials need more time or more heat than others to be at their full potential. For an extensive list click here.

How to Use It

As you may have noticed, Formlabs has a special obsession with wanting to make things as simple as possible while blowing your mind and it’s no wonder that the Form Cure follows in the same pathway. Using the Cure is easy: you put the part(s) in the machine, close the door, select your setting and press start.

The holed support plate will then rotate to allow dispersion of the heat and 12 UV lights to reach every part of the printed pieces over the preselected amount of time. The UV lights with the back mirror look like something out of this world that hypnotize you which makes the time go by much faster. Like we said, complete solution.

Voxel Factory Tip/Precision

One thing to note, if you decide to leave support on the prints while curing, there might be deformation during the curing process due to heat, depending on the material use and the complexity of the print. We had a case like that with the Durable resin where the supports deformed. This can be explained by the low heat resistance of the Durable resin and the insufficient amount of support in the print. We asked the materials experts when we visited them and they advised us to, first, if possible to take off supports and, second, to reduce the heat by a few degrees if the supports are really needed to hold the piece together. Another option is to add more support to support the piece from gravitational deformation.

One thing to note, if you decide to leave support on the prints while curing, there might be deformation during the curing process due to heat, depending on the material use and the complexity of the print. We had a case like that with the Durable resin where the supports deformed. This can be explained by the low heat resistance of the Durable resin and the insufficient amount of support in the print. We asked the materials experts when we visited them and they advised us to, first, if possible to take off supports and, second, to reduce the heat by a few degrees if the supports are really needed to hold the piece together. Another option is to add more support to support the piece from gravitational deformation.

Form Cell Compatibility

Side note, the Form Cure is not compatible with the Form Cell (or at least not yet). The reason is simple, the automated arm of the Form Cell grabs the build plate from the Form 2 and transfers it to the Form Wash, it could technically transfer the build plate into the Form Cure.

However, the bottom of the part would not be cured, and the build plate would be rendered useless afterwards since the resin particles would be cured on the plate making it impossible to reuse.

Formlabs Services at Voxel Factory

At Voxel Factory, with every purchase of a Form 2, we offer a free 3 hours hands-on workshop to explain everything you need to know to operate your printed at maximum efficiency. We look both at hardware and software.

Certified Service

Outside of Formlabs, Voxel Factory and our very own William Puchot is the first certified person in North America allowed to operate, maintain and provide technical support for Formlabs machines.

This assures that your machines will be well taken care of especially in difficult times where professional reliable help is needed.

Formlabs Warranty

The Form 2 comes with a standard 1-year manufacturer's warranty that can be expanded for an extra year.

Warranty includes repairing, replacing or exchanging parts at no extra cost for neither the physical parts nor the labour.

If you wish to take advantage of this warranty, ask us for a quote.

Find all the details and fine print here.

- Tags: Formlabs SLA 3D Printing

- Nathan Orfin